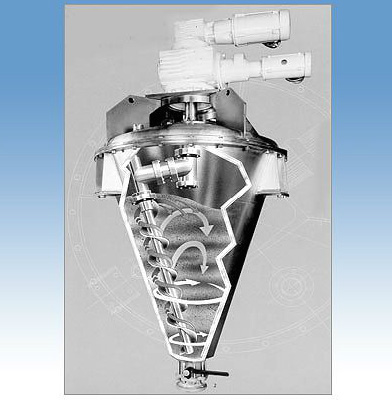

How the Vertical Blender works

Vertical Blenders are an excellent design alternative for applications that are shear sensitive or where space on the plant floor is at a minimum. The gentle blending action of the slow turning blending screw is far gentler than that of a horizontal blender. The blending screw orbits the conical vessel wall while it turns and gently lifts material upward. The materials are then thrust at the upper most batch level towards the center of the vessel, and then move slowly back down the center, while mixing with materials being moved upward by the orbiting screw.

Video in Action

In this demonstration, first we see the action of the mixing screw without any material in the vessel.

The next view is of the screw rotating throughout the batch of granular light colored product. A dark colored product is then introduced to the batch and very shortly is completely dispersed.

After discharge, the close-up shows the success of the demonstration.

Additional Information

Related Articles, Mixing Technology Insights and Whitepapers

Asking the right questions about vertical blenders

Large-scale vacuum drying in a Vertical Blender

Recommended Mixing Equipment for Plastic Resins

Vertical blender/dryers deliver high drying rates with negligible risk of product attrition.