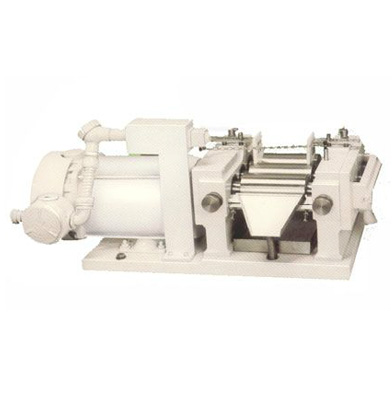

How the Three Roll Mill works

Materials are added between the feed and center rolls. The materials are then transferred to progressively higher speed center and take off rolls. As the materials progress, they are sheared by the action created by the differential speeds of the rolls and the shearing created by the clearances between the rolls.

Once the materials reach the exit point from the highest speed roll, they are cleaned off the roll by a sharp knife attached to the take off apron.

Video in Action

The material to be milled is placed between the feed and center rolls. Each adjacent roll rotates at progressively higher speeds. For example; the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm.

Material is transferred from the center roll to the apron roll by adhesion. The dispersion is achieved by the shear forces generated between the adjacent rolls. The milled material is removed from the apron roll by a knife that runs against the roll.

Additional Information

Related Articles, Mixing Technology Insights and Whitepapers

Best practices for safe and efficient three roll milling

Create smooth, speck-free pastes in your Three Roll Mill.

Upgrade your ball mill process by switching to a three roll mill.