How the Static Mixers - ISG works

The ISG (interfacial surface generator) consists of individual mixing elements that are stacked in a tubular housing. The ends of the elements are shaped so that the adjacent elements form a tetrahedral chamber. Four holes bored through each element provide the flow paths. The holes are at oblique angles so that material near the periphery (i.e. near the pipe wall) on the inlet side of the element emerges near the center on the outlet side. The material exiting one element then enters near the center into the second element and exits near the wall. This radial mixing eliminates the wall smearing effect that can be otherwise encountered when mixing viscous materials.

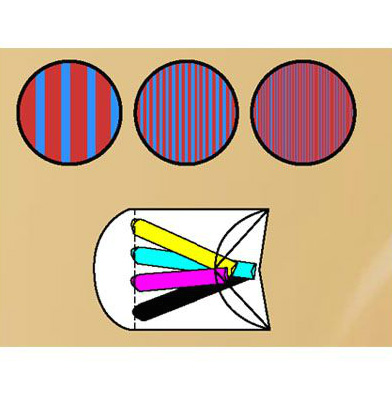

Cross Section of the ISG Static Mixer

As product flows through an ISG element, it is layered 4 times per element. Thus after passing through 4 elements, 2 components have been layered 256 times.

Additional Information

Related Articles, Mixing Technology Insights and Whitepapers

Choosing the right static mixer design for viscous mixtures