Ross Inline High Shear Mixers Produce Flocculants for Industrial and Municipal Wastewater Plants

Tuesday, June 25, 2019

BACKGROUND:

Flocculants are chemicals that are specifically designed to form agglomerations, usually in an aqueous medium, such as wastewater.

When the compound that is desired to be removed comes in contact with the flocculant, an agglomeration is formed. The resultant agglomerate is then able to be filtered and removed from the effluent stream.

Millions of gallons of flocculants are used yearly in wastewater treatment facilities all over the world.

APPLICATION:

Two Ross Inline High Shear Mixers, Model HSM-4100 (100 HP) are in service at one client's facilities, each producing 3,000 gallon batches of polyelectrolyte based flocculants.

PROCESSING:

The manufacturing of polyelectrolyte based flocculants involves bringing together a 4-constituent aqueous phase with a 3-constituent oil phase, to produce a 3,000 gallon batch.

All of the constituents are introduced to the 3,000 gallon tank. The batch is recirculated through the 100 HP High Shear Mixer until complete - approximate batch time is 2.5 hours.

When the batch is finished, the flocculant is again pumped through the High Shear Mixer, on its way to a storage vessel. The finished product is shipped to industrial and municipal wastewater treatment facilities via bulk tankers and also in 55-gallon drums.

MIXER SPECIFICATIONS:

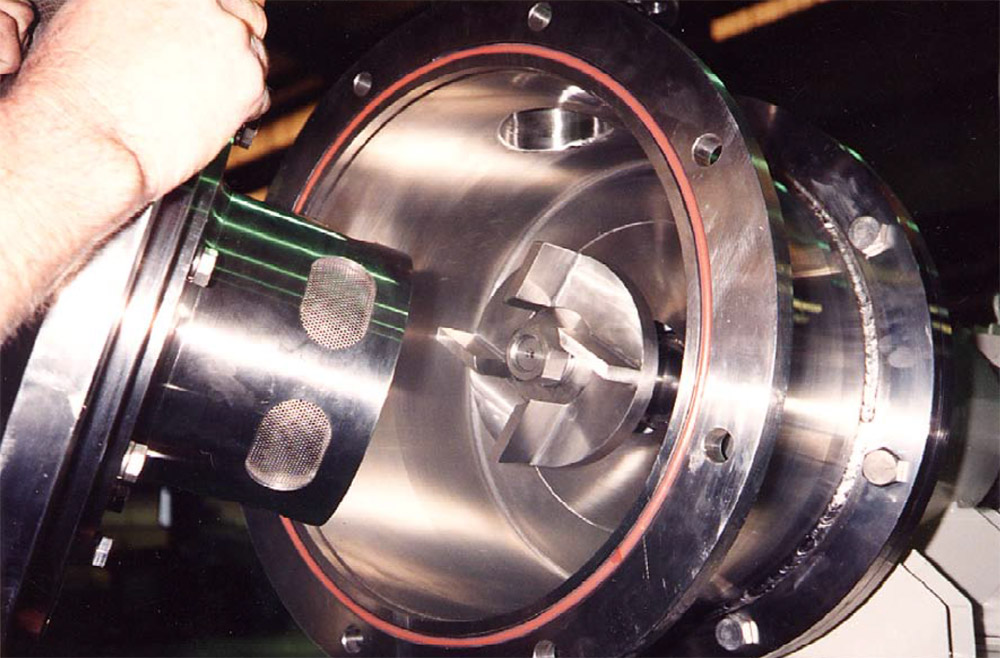

The Inline High Shear Mixer HSM-4100 used for the production of flocculants includes the following specifications:

- 100 HP, single speed, 230/460 volt, 3 phase TEFC motor

- Double mechanical seal with tungsten carbide/carbon faces

- Special reinforced fine screen head with 1/16" holes staggered on a 1/8" pattern.

- Carpenter 20 rotor shaft to resist chloride ion attack

Application Note: Both units referenced in this case history are reportedly working extremely well. They have been operating successfully for over two decades.

Special fine screen head enables the 100 HP inline Mixer Emulsifier to achieve excellent

dispersion in the processing of flocculants.