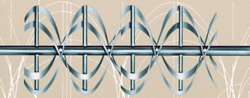

How the Ribbon Blender Works

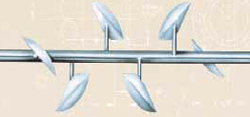

Ribbon Blenders consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer helical agitators. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 300 fpm moves materials both radially and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 100% of the rated capacity of the blender.

An alternate agitator is our paddle design. The paddles are positioned to move materials in opposing lateral directions and radially. The paddle design is normally applied where friable materials are being blended and when batches as small as 15% of the total capacity are going to be mixed in one blender.

Ribbon and Paddle designs are available in working capacities to over 515 cu.ft. and in either center or end discharge designs. (BISSC certified)

-

Sanitary Lab Model 1 Cu Ft

Sanitary Lab Model 1 Cu Ft

-

Lab Model 1 Cu Ft - Special Valve

Lab Model 1 Cu Ft - Special Valve

-

Sanitary Vacuum/Pressure 5 cu.ft.

Sanitary Vacuum/Pressure 5 cu.ft.

Specifications Laboratory Specifications (open full size view)

Specifications Laboratory Specifications (open full size view)

-

515 Cu Ft Model

515 Cu Ft Model

-

120 Cu Ft Ribbon Blender

120 Cu Ft Ribbon Blender

-

52 Cu Ft Vacuum Ribbon Blender

52 Cu Ft Vacuum Ribbon Blender

-

Sanitary Screw Discharge Model

Sanitary Screw Discharge Model

-

Sanitary Model

Sanitary Model

-

Cylindrical Paste Mixer

Cylindrical Paste Mixer

Specifications Production Specifications (open full size view)

Specifications Production Specifications (open full size view)