How the Tilt Type Kneader Works

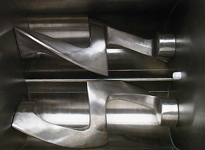

The sigma blade mixer includes two blades that rotate toward each other at differential speeds. Each blade moves the material in opposite directions thereby providing excellent cross mixing of all raw materials. The blades pass the trough walls and each other at close clearances. This close clearance action provides a shearing and tearing action that is beneficial to the size reduction of solids such as rubber and plastic pellets.

Once the mix cycle is complete the trough of the mixer is tilted and the mixture is discharged to a secondary container for transfer to packaging or to downstream operations.

-

40 Liter Model

40 Liter Model

-

Sanitary Model

Sanitary Model

-

630 Liter Model

630 Liter Model