How the Series 100 Batch High Shear Mixer Works

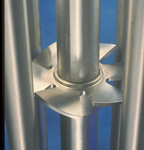

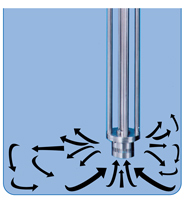

The Batch High Shear Mixer design consists of a single stage four-blade rotor that turns at high speed within a stationary stator. As the rotating blades pass each opening in the stator, they mechanically shear particles and droplets, and expel material at high velocity into the surrounding mix, creating intense hydraulic shear. As fast as material is expelled, more is drawn into the bottom of the rotor/stator generator, which promotes continuous flow and fast mixing.

The batch model can be either mounted to a vessel or suspended over a vessel on a portable lift. The mobile configuration offers the flexibility to use a single mixer in multiple vessels. It also allows the user to vary the position of the stator to process different materials and batch sizes.

The rotor/stator of the batch model is generally positioned 2 - 3 head diameters off the bottom of the vessel, and slightly off center. To ensure adequate suspension of heavier solids, the rotor/stator generator may be positioned in the center of the vessel. Interchangeable stators provide unlimited flexibility to adapt to a variety of product formulations.

Batch models are supplied in many sizes from 3/4 through 100 horsepower.

1) High Shear Website - English

2) High Shear Mixers - Chinese

3) High Shear Mixers Website - Spanish

-

Model HSM 100 LCI-T

Model HSM 100 LCI-T

-

Model HSM 100 LSK-I

Model HSM 100 LSK-I

-

Model HSM 100 LCI-T-Disperser

Model HSM 100 LCI-T-Disperser

-

Model HSM 100 LH2

Model HSM 100 LH2

Model 100LCI-T Laboratory Specifications (open full size view)

Model 100LSK-I Laboratory Specifications (open full size view)

Model 100LCI-T Laboratory Specifications (open full size view)

-

Series 100 Model

Series 100 Model

-

Hydraulic Lift Model

Hydraulic Lift Model

Series 100 Batch Models Production Specifications (open full size view)