How the Inline Rotor Stator Mixers Works

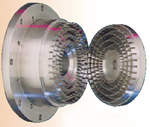

The Inline Model High Shear Rotor-Stator mixer design consists of a single, dual or four stage rotor that turns at high speed within a stationary stator. As the rotating blades pass the stator, they mechanically shear the contents.

The Inline model is a good choice for process lines that require frequent changeover from one product to another. A simple valve can divert finished product downstream or switch instantly from one vessel to another.

Interchangeable rotor-stator combinations provide unlimited flexibility to adopt to a variety of product formulations

The Inline models are supplied in many sizes and materials of construction from 1/2 through 150 horsepower. (Our in line high shear mixers are 3A approved)

1) High Shear Website - English

2) High Shear Mixers - Chinese

3) High Shear Mixers Website - Spanish

-

Model HSM 400 DLA

Model HSM 400 DLA

-

Model HSM 100 LCI-T with Inline Attachment

Model HSM 100 LCI-T with Inline Attachment

400DL Laboratory Inline Laboratory Specifications (open full size view)

-

Model 400 Inline

Model 400 Inline

-

Model 400 Vertical with recirculation vessel

Model 400 Vertical with recirculation vessel

-

Inline Mix System

Inline Mix System

-

Sanitary Inline with Vessel

Sanitary Inline with Vessel

-

Portable Sanitary System

Portable Sanitary System

-

Continuous Duty Design

Continuous Duty Design

Series 400 Inline Models Production Specifications (open full size view)