Reduce cycle time in your large capacity mixer.

Technology Brief

This bulletin discusses a method of raw material handling and addition that simplifies large capacity mixing and can reduce cycle times by up to 80%.

Batch mixing by the bulk

In batch mixing, cycle time is often a function of many factors including solubility, ease of dispersion, particle size reduction, emulsification, reaction kinetics, heating/cooling rates, etc. In large scale operations, the method of raw material addition becomes another critical parameter. For example, when a good portion of the raw materials are solids that need to be dispersed or dissolved into liquid, charging them from the top of the batch can become complicated if they tend to dust or float on the liquid surface. Some powders, such as gums and thickeners, form tough agglomerates when added too quickly, even when the batch is being agitated vigorously. This forces operators to deal with very slow powder additions. In extreme cases, solid raw materials are added deliberately fast but at an overdosed rate so that any undispersed agglomerates are simply filtered out after the mixing cycle. Fortunately, new opportunities exist to supplement conventional batch agitators, improve handling, conserve raw materials and optimize cycle time.

A better way to add powders and boost production

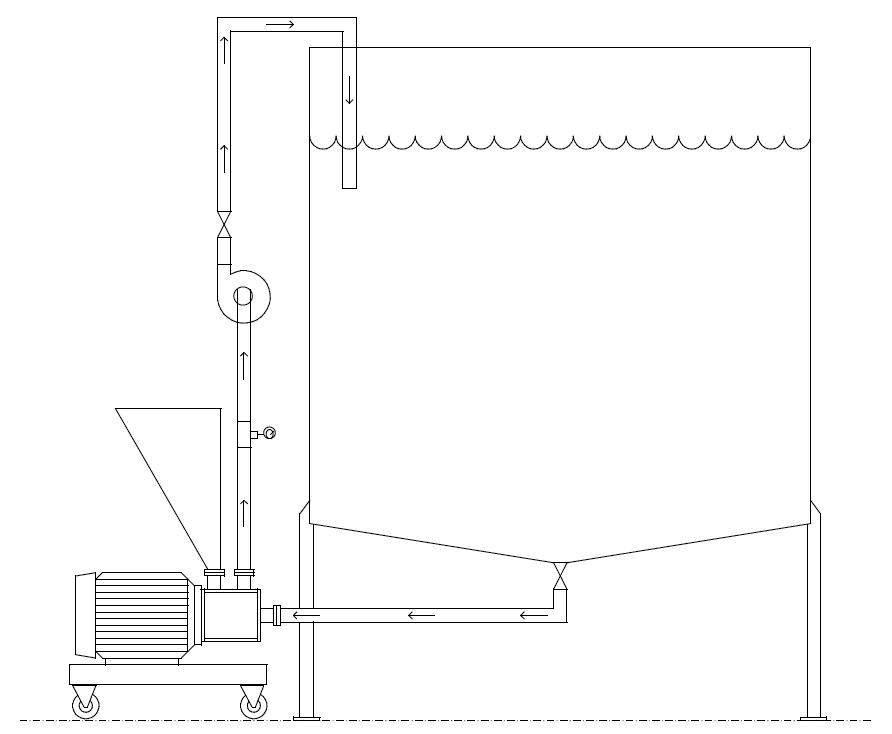

Any large batch mixing operation that involves solids dispersion or dissolution into a flowable liquid can typically benefit from an inline powder injection system such as the Ross Solids/Liquid Injection Manifold (SLIM). This is an external mixer piped to the main tank like a pump in a recirculation loop.

Solids are injected into the recirculating liquid stream right within the high shear zone of the rotor/stator mix chamber. Based on user experiences, this method of powder addition routinely cuts cycle times by 80% or more.

At the heart of the process is a unique rotor/stator designed to generate a powerful vacuum that draws powders into the mix chamber and simultaneously disperses them into liquid. The resulting mixture is expelled through the slots of the stator at high velocity. When used with large tanks or reactors which are mostly stirred by slow speed agitators, the inline SLIM delivers sufficient shear for reducing particle size and even prevents agglomerates from forming in the first place. The rapid product turnover via recirculation through the high speed rotor/stator mixer also helps to keep solids suspended in the batch so they can dissolve faster or simply maintain a uniform dispersion.

Reduce dusting, too.

Handling lightweight powders through the SLIM is advantageous as it eliminates dust-generating transfer steps. A hose & wand device may be attached to the powder inlet of the SLIM to allow the operator to simply draw powders straight from the original sack or container. Powders that are easier to handle may be fed through a hopper. This can be done manually or through automatic feeding equipment.

At a facility manufacturing sterile sodium chloride solutions, operators used to pre-weigh powders and climb up a mezzanine to manually charge the solids into six 500-gallon tanks. In an effort to update their mixing procedure, increase throughput and improve operator safety, the company installed an inline SLIM mixer in the weighing section, piped to all six tanks. An operator now weighs solids right in the hopper, turns on the mixer and simply opens the induction valve to introduce powders into the batch. Piping valves allow the operator to easily switch from one recirculation tank to another.

Sample Application: Ophthalmic Solutions