How the Vacuum Ribbon Blender Works

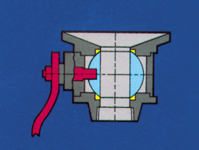

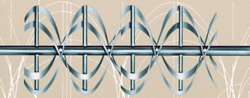

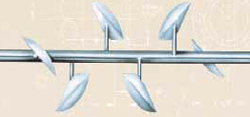

Ribbon Blenders consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. The agitator consists of a set of inner and outer helical agitators that provide vigorous lateral and radial movement of the bulk material. The ribbon rotates at approximately 350 fpm and ensures thorough blends within short cycle times. An alternate agitator is our paddle design which applies gentler blending better suited for friable materials. Either agitator design can typically accommodate as low as 25% of the blender's maximum working capacity. Vacuum enables faster drying and solvent recovery at lower operating temperatures. A deaerated environment may also promote better interaction between discrete particles leading to enhanced homogenization and faster integration of minor additives such as scents, flavors, colors and APIs.

-

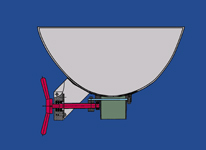

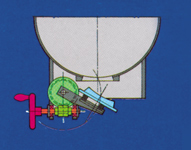

18 Cu.Ft. Vacuum Blender

18 Cu.Ft. Vacuum Blender

-

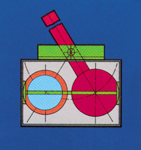

100 Cu.Ft. Vacuum Paddle Design

100 Cu.Ft. Vacuum Paddle Design

Specifications Production Specifications (open full size view)