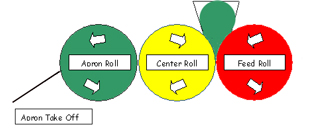

How the Three Roll Mill Works

The material to be milled is placed between the feed and center rolls. Each adjacent roll rotates at progressively higher speeds. For example; the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm. Material is transferred from the center roll to the apron roll by adhesion. The dispersion is achieved by the shear forces generated between the adjacent rolls. The milled material is removed from the apron roll by a knife that runs against the roll.

-

4 x 8 Three Roll Mill

4 x 8 Three Roll Mill

-

2 1/2 x 5 Three Roll Mill

2 1/2 x 5 Three Roll Mill

Specifications Laboratory Specifications (open full size view)