How the Double Planetary Mixer Works

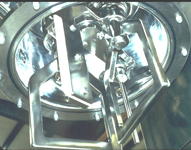

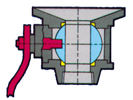

The Double Planetary Mixer includes two blades that rotate on their own axes, while they orbit the mix vessel on a common axis. The blades continuously advance along the periphery of the vessel, removing material from the vessel wall and transporting it to the interior. After one revolution the blades have passed through the entire vessel, after three revolutions most materials have been mixed and after only 36 revolutions, the blades have contacted virtually the entire batch.

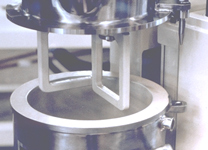

Ross pioneered Change Can mixer design nearly 100 years ago. Today we offer many of our mixers with this option which can dramatically increase production in your plant. While one vessel is wheeled away for remote discharge and cleaning, another wheels into place to start the next batch immediately.

Ross Planetary Mixers have been the world's leader for the last 80 years. Today it still surpasses all others in both productivity and long-term reliability. With no packing glands or bearings in the product zone, contamination is virtually eliminated.

HV Blade design shown in animation is patented.

This mixer is ideal for mixing and kneading viscous pastes or putty-like materials. Capacities from 1/2-pint through 400 gallons. A wide variety of options include vacuum/pressure, thermal jacketing and sanitary designs.

For more information on Planetary Mixers, click here.

The Double Planetary Mixer includes two blades that rotate on their own axes, while they orbit the mix vessel on a common axis. The blades continuously advance along the periphery of the vessel, removing material from the vessel wall and transporting it to the interior.

After one revolution the blades have passed through the entire vessel, after three revolutions most materials have been mixed and after only 36 revolutions, the blades have contacted virtually the entire batch.

The Double Planetary Mixer includes two blades that rotate on their own axes, while they orbit the mix vessel on a common axis. The blades continuously advance along the periphery of the vessel, removing material from the vessel wall and transporting it to the interior.

After one revolution the blades have passed through the entire vessel, after three revolutions most materials have been mixed and after only 36 revolutions, the blades have contacted virtually the entire batch.

NOTE: The "HV" blades shown in the animation are patented.