How the Cylindrical Dryer Works

The horizontal cylindrical dryer design includes either a ribbon or paddle agitator, depending on the materials and the range of volumes to be dried. The agitator efficiently moves the materials within the vessel, past the jacketed trough walls until the desired moisture content is achieved. Cylindrical dryers are available from .33 to 343 cu.ft. working capacity, and can be supplied with a wide range of features to suit each clients special needs.

-

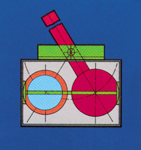

42C-155 Cylindrical Blender/Dryer

42C-155 Cylindrical Blender/Dryer

-

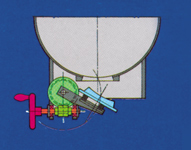

42C-100 Cylindrical Blender

42C-100 Cylindrical Blender

-

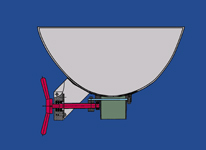

42C-10 Cylindrical Dryer

42C-10 Cylindrical Dryer

-

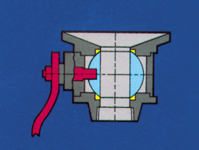

42C-18 Sanitary Cylindrical Ribbon Blender

42C-18 Sanitary Cylindrical Ribbon Blender

Specifications Production Specifications (open full size view)